Location: Home > Capability > High Level Assembly

Fully understood customer needs, combined with the Ahwit long-term development strategy and industrial upgrading, we gradually start from the precision manufacturing of parts and components to the high level assembly and strive hard to achieve international advanced level.

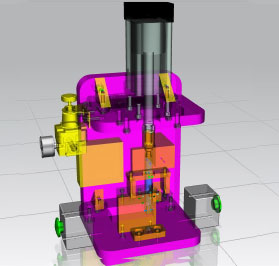

Assembly Engineering Capability

Assembly Modeling, Assembly Dimension Chain Calculating

Finite Element Method (stress, strain, strength, vibration, fatigue, liquid )

Simulation, Assembly (static/dynamic load, assembly clearance)

Interference Detection & Analysis

Become a global reputable company and a benchmark in high precision mechanical parts fabrication and high level assembly.

Process Quality Inspection

Finish Goods Inspection

Outgoing Quality Control

U type layout

Assembly Tools

Testing Tooling

OEM Services

Material Management

Work Instruction

Inspection Procedure

Adapt to the needs of new technologies, new processes, new equipment, new materials development.